Expanding research on the fluidity of shield tail sealing grease

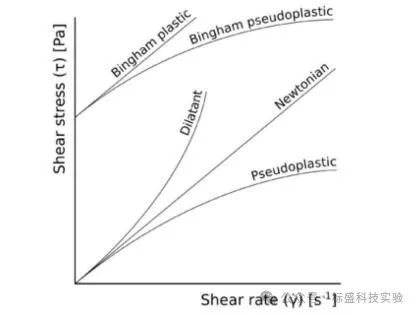

As is well known, the pumping performance of shield tail sealing grease has always been a highly concerned issue in construction, and as a fluid that approximates a solid, shield tail sealing grease still conforms to the characteristics of fluid mechanics. For this purpose, we conducted a series of fluid dynamics studies on shield tail sealing grease. As a typical non Newtonian fluid, its shear stress and shear rate during flow in pipelines meet the characteristics of Binghan plastic fluid

In order to study the pumping performance characteristics of shield tail sealing grease, we introduced the concept of apparent viscosity curve. In order to obtain the most accurate apparent viscosity curve, we need to τ Analyze and test at 0 (yield stress). Although the closest curve can be fitted through a large amount of data fitting, if it can be measured τ 0, then the starting position of the curve will be accurately defined. That is to say, at least how much stress is required for the sealing grease at the tail of the shield to start flowing. This has significant implications for the changes in oil performance at different temperatures

In order to more accurately study the yield stress value of oil flow, we used a low-temperature fluidity tester for lipids

Through this device, we have achieved the goal of accurately controlling temperature for sample testing in a laboratory room temperature environment, and provided a basis for future verification and research on temperature impact changes. In the future, shield tail sealing grease can be tested for pumping capacity and usage effectiveness at different temperatures in a conventional laboratory environment. I believe this is something worth looking forward to for the development of the rail transit industry. And we will continue to be committed to meeting the customer's needs and answers for testing methods and practical use of shield tail sealing grease performance indicators

In order to study the pumping performance characteristics of shield tail sealing grease, we introduced the concept of apparent viscosity curve. In order to obtain the most accurate apparent viscosity curve, we need to τ Analyze and test at 0 (yield stress). Although the closest curve can be fitted through a large amount of data fitting, if it can be measured τ 0, then the starting position of the curve will be accurately defined. That is to say, at least how much stress is required for the sealing grease at the tail of the shield to start flowing. This has significant implications for the changes in oil performance at different temperatures

In order to more accurately study the yield stress value of oil flow, we used a low-temperature fluidity tester for lipids

Through this device, we have achieved the goal of accurately controlling temperature for sample testing in a laboratory room temperature environment, and provided a basis for future verification and research on temperature impact changes. In the future, shield tail sealing grease can be tested for pumping capacity and usage effectiveness at different temperatures in a conventional laboratory environment. I believe this is something worth looking forward to for the development of the rail transit industry. And we will continue to be committed to meeting the customer's needs and answers for testing methods and practical use of shield tail sealing grease performance indicators